A little over a year ago, we started the exciting project with Norman Koerschulte and the company Koerschulte + Werkverein to set up a pilot operation for an inner-city delivery logistics route, which has led to a close partnership.

The company Koerschulte is established as a tier 2 supplier for tools and accessories, especially in the automotive sector, and is a renowned address in the Ruhr area and Sauerland. This is also how we got to know the company and Norman – 3EA as a customer for 3D printed parts at Koerschulte. We got into conversation with Norman, who himself has worked in aviation for a long time and has a corresponding passion.

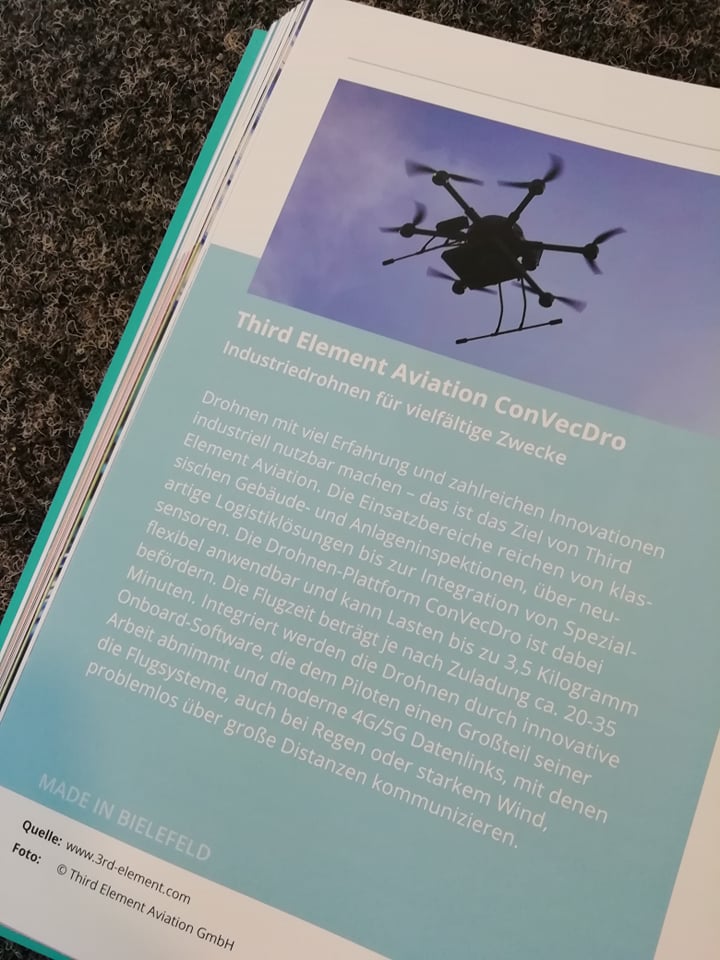

Norman’s vision of setting up his own drone airline for delivery logistics resulted impressively fast in a pilot project in which the Koerschulte company supplies a customer with urgently needed tools and accessories over an approved distance of approx. 2 kilometers in automated operation beyond visual range. Thus, the pilot project turned into a test phase with regular deliveries.

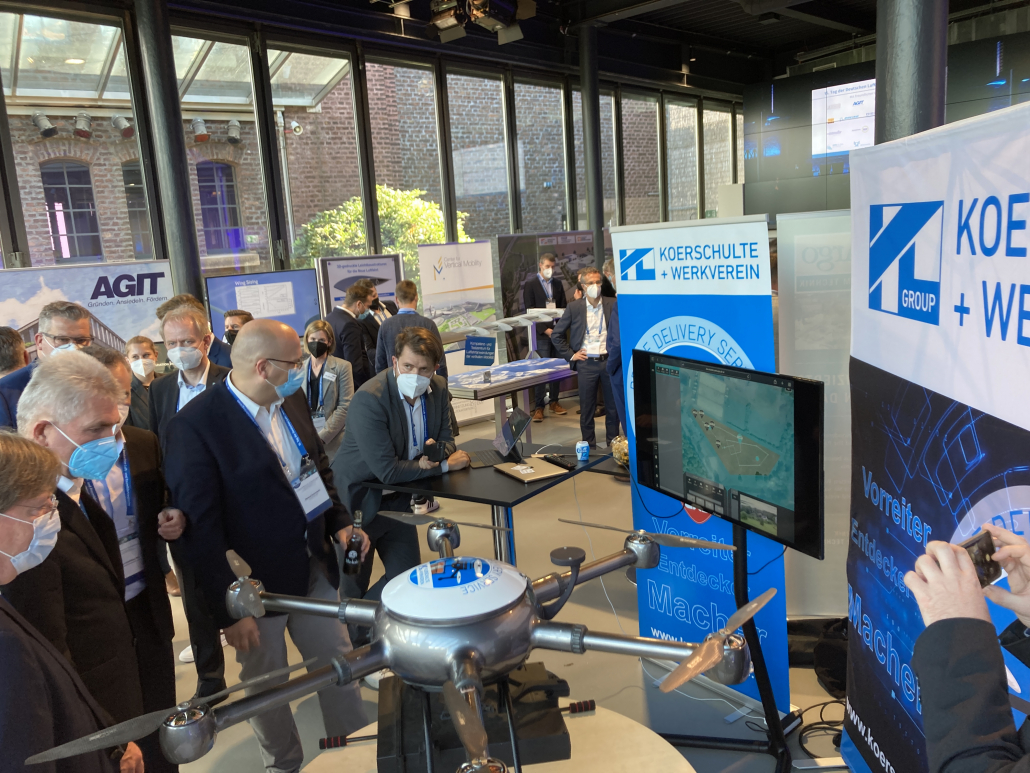

While logistics drones are already used more frequently on factory premises, this is the first successful delivery drone project outside a company’s own factory premises with regular operations in Germany. The response in the industry and in the media was correspondingly great. Since then, we have also been represented together at various trade fairs and events.

In the meantime, we have already been able to develop extended features such as manual landing monitoring during automated operation for landings on busy factory premises or specific fail-safes.

Based on the first joint successes, the fleet is to be expanded next year using larger systems, also further delivery routes are to be set up. Koerschulte aims to establish itself as the first drone airline for drone operations, initially in the German region – with 3EA as a development partner and hardware supplier at its side.

We are very excited about this partnership and the upcoming projects.

#drones #3EA #UAV #koerschulte #airline #supplychain